Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

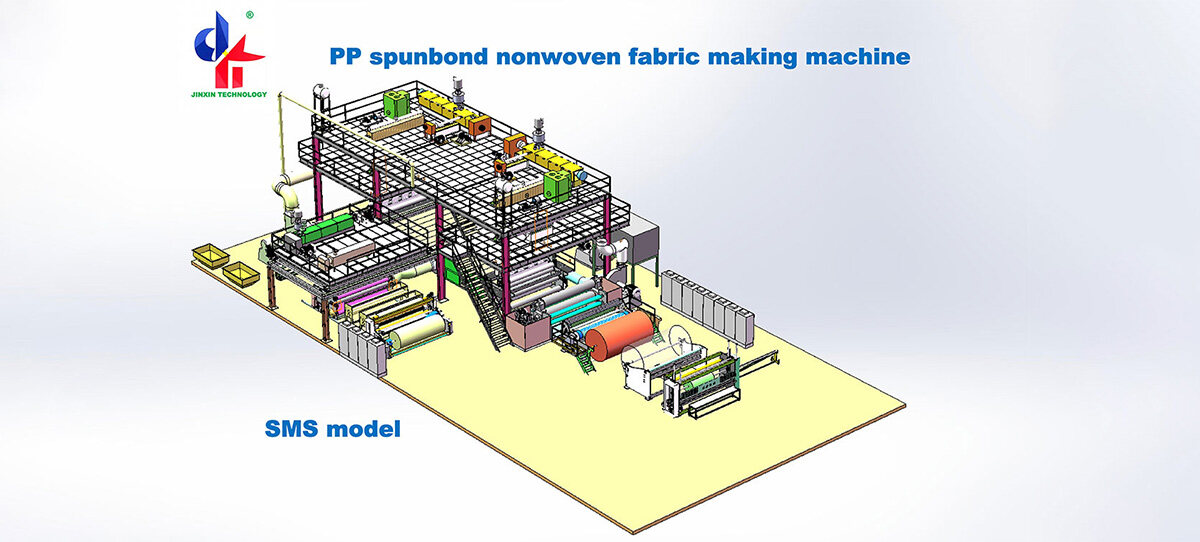

Machine de tissu non tissé SMS 1600mm

Medium-thickness SMS non-woven fabric is ideal for both industrial and medical applications, including the creation of work clothes and protective gear as well as surgical garments, sterilization bandages, wound patches, plasters, and surgical bag cloths.

| Model | JX-SMS |

|---|---|

| Product Width | 1600mm |

| Equipment Size | 40*16*12m |

| Mechanical Speed | 400m/min |

| Gram Weight | 10-150g/m2 |

| Daily Output | 8-12T/Day |

| Transformer Capacity | ≈800KVA |

| Power Consumption | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The manufacturing process of SMS non-woven fabric

3%-7% masterbatch was added in the spinning production of SMS non-woven fabric; Preparation of functional additives: functional additives are made by mixing waterproof agent, flame retardant, antistatic agent, penetrant, and water; The SMS non-woven fabric is placed in the impregnation liquid tank with functional additives for impregnation, drying, drying and cooling to obtain the desired multifunctional SMS non-woven fabric.

SMS non-woven fabric product performance

Nontoxic and tasteless, highly effective bacteria isolation. Through special treatment of the equipment, it can achieve anti-static, anti-alcohol, anti plasma, water repellent, and water producing properties.

Application of SMS non-woven fabric

1.The thin SMS non-woven fabric is especially suitable for the sanitary napkin Market, such as sanitary napkins, sanitary pads, baby diapers, adult incontinence diapers, etc. due to its waterproof and air permeability.

2.Medium thickness SMS non-woven fabric, suitable for medical use, such as making surgical clothing, surgical bag cloth, surgical cover cloth, sterilization bandage, wound patch, plaster, etc., and also suitable for industrial use, such as making work clothes and protective clothing.

3.Thick SMS products are widely used as high-efficiency filter materials for various gases and liquids. At the same time, they are also excellent high-efficiency oil absorbing materials, which are used in industrial wastewater oil removal, marine oil cleaning, and industrial rags.

Special process of SMS non-woven fabric

Various special treatments for non-woven fabrics can meet the requirements of customers for various special properties of non-woven fabrics. The treated non-woven fabric has the functions of anti-alcohol, anti-blood, and anti-oil, and is mainly used in medical surgical clothes and surgical sheets.

Antistatic treatment: Antistatic non-woven fabric is mainly used for the materials of protective articles with special environmental requirements for static electricity.

Water absorption treatment: water absorption non-woven fabric is mainly used in the production of medical consumables, such as surgical hole towels, surgical pad sheets, etc.

Flame retardant treatment: flame retardant non-woven fabrics are widely used in furniture products and aviation supplies.

Antibacterial and odor prevention and photocatalyst effect treatment: this kind of non-woven fabric is mainly used in the field of household goods.

Anti ultraviolet treatment: anti-ultraviolet and anti-aging non-woven fabrics are mainly used for agricultural covering cloth, automobile covers, and other fabrics, and are required to have sun protection and anti-aging effects.

Fragrance treatment: Fragrance non-woven fabric is applied to sanitary products (including mint flavor, lemon flavor, lavender flavor, etc.).